Advantages of Cuplock Scaffolding:

* Easy to erect and dismantle. Just a simple locking cup at each node point on the standards enables connection of the ends of up to four members in one locking action without nuts and bolts or wedges.

* Versatile. Best suitable for access or formwork support.

* Timely tested and Proven design with safety accessories. Cuplock System has a proven performance history on an extensive number of sites, meeting the requirements of the various statutory bodies.

* Quick fastening of horizontals. Only 4 horizontals can be fastened at one time with firm clamping action of top cup making the joint rigid.

* Quick/Fast/Solid erection and dismantling results in time and labour saving.

* Widely and Versatile use in construction, demolition or maintenance projects for any type of structure i.e. straight or curved.

* Lightweight but high loads carrying capacity.

* Low maintenance.

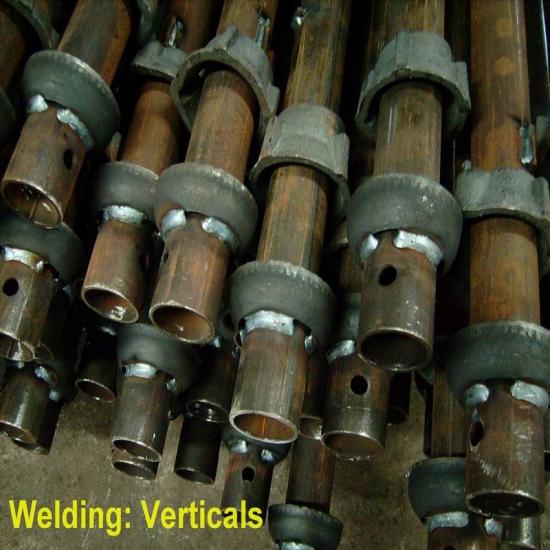

Cup Lock Scaffolding Standard / Vertical (Spigoted)

Product Details:

Code

Description

Material

Size

Weight (kg)

Weight (lbs)

CS.S.300

3.00M Standard

Ø48.3x3.25mm; Q235-Q355

3000mm (9'10")

15.47

34.11

CS.S.250

2.50M Standard

2500mm (8'2")

13.02

28.71

CS.S.200

2.00M Standard

2000mm (6'7")

10.58

23.33

CS.S.150

1.50M Standard

1500mm (4'11")

8.14

17.95

CS.S.100

1.00M Standard

1000mm (3'3")

5.69

12.55

CS.S.050

0.50M Standard

500mm (1'8")

3.25

7.17

CS.S.031

0.31M Standard

305mm (1')

2.55

5.62

Features:

Tube Dimension: O.D 48.3x3.25mm. Other tube thickness 4.0mm/3.5mm/3.0mm is also available by request.

Spigot Size: O.D 38x3x300mm or SHS30x30x3x300mm

Steel Tube Grade: Q235-Q355

Cup Distance: 500mm

Surface Finishing: Hot dip Galvanized; Powder Coated, Painted

Quality Standard: EN12810 / BS1139

Welding Process: CO2/Mixture gas Shielding Welding